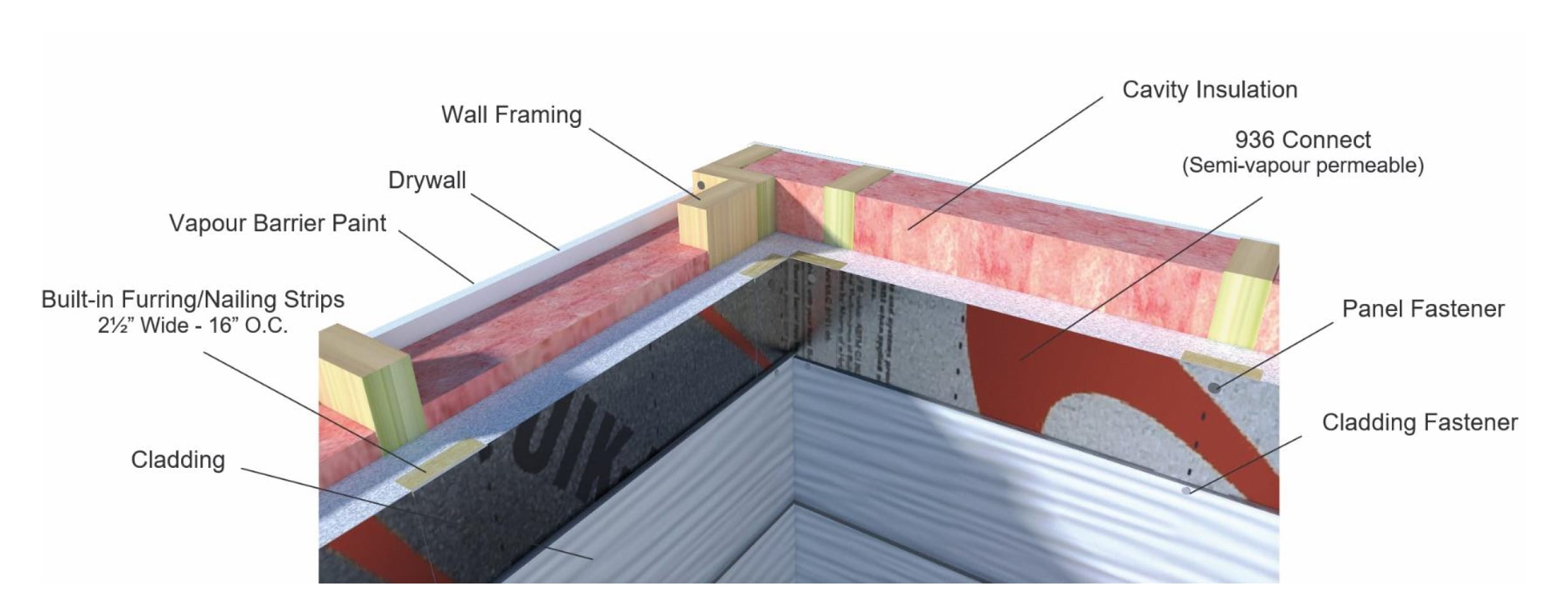

936 Connect

Composite Wall Weathering System

SAVE ON COSTS!

NOT REQUIRED:

*OSB EXTERIOR SHEATHING

*EXTERIOR BUILDING WRAP

*INTERIOR WALL POLY

*Lean construction. *Installs with a framing nailer. *Achieve passive house ACH. * Superior hydrothermal + R-valve performance.

936 Connect is a composite Lean Construction, low cost, energy and carbon saving wall weatherization system. 2×4 framed 936 Connect walls cost less, install faster and provide 30%+ superior effective R-value performance compared to 2×6 minimum code wall assemblies. In Canada, 9.36 applies to energy efficiency code requirements as they apply to construction of new homes and small buildings. 936 Connect is 9.36 National Building Code compliant in most Canadian jurisdictions.

Scope & Purpose

This document describes the recommended best practices for installing 936 Connect (936) in wood framed structures. Specific installation conditions and environment may warrant digression from these instructions. For example, exterior sheathing is an NBCC requirement in seismic (earthquake) prone regions.

In all instances, refer to the notes included with each installation schematic to ensure the technical advantages of the product are maintained. **** Adhere to local building codes.

Technical Advantages

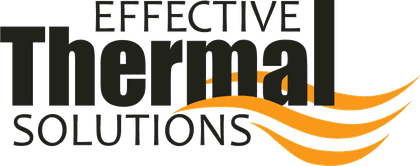

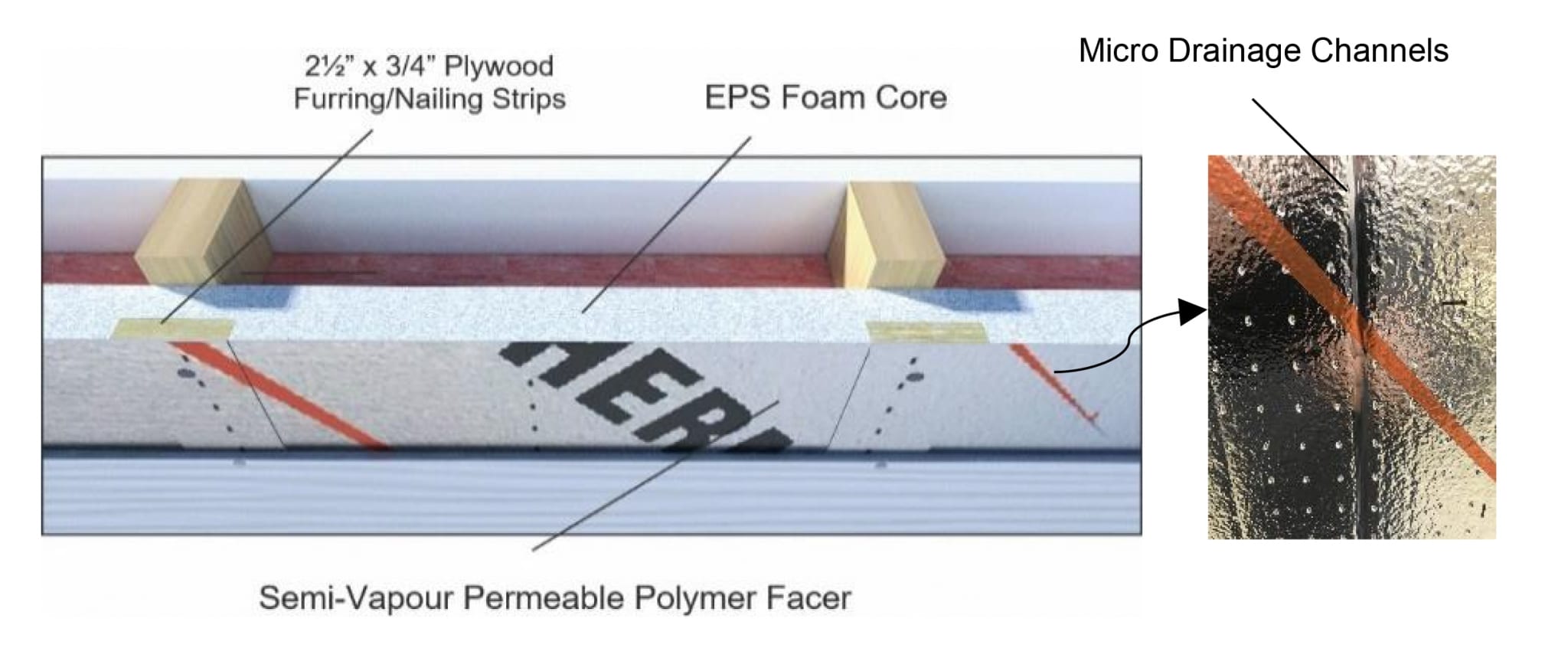

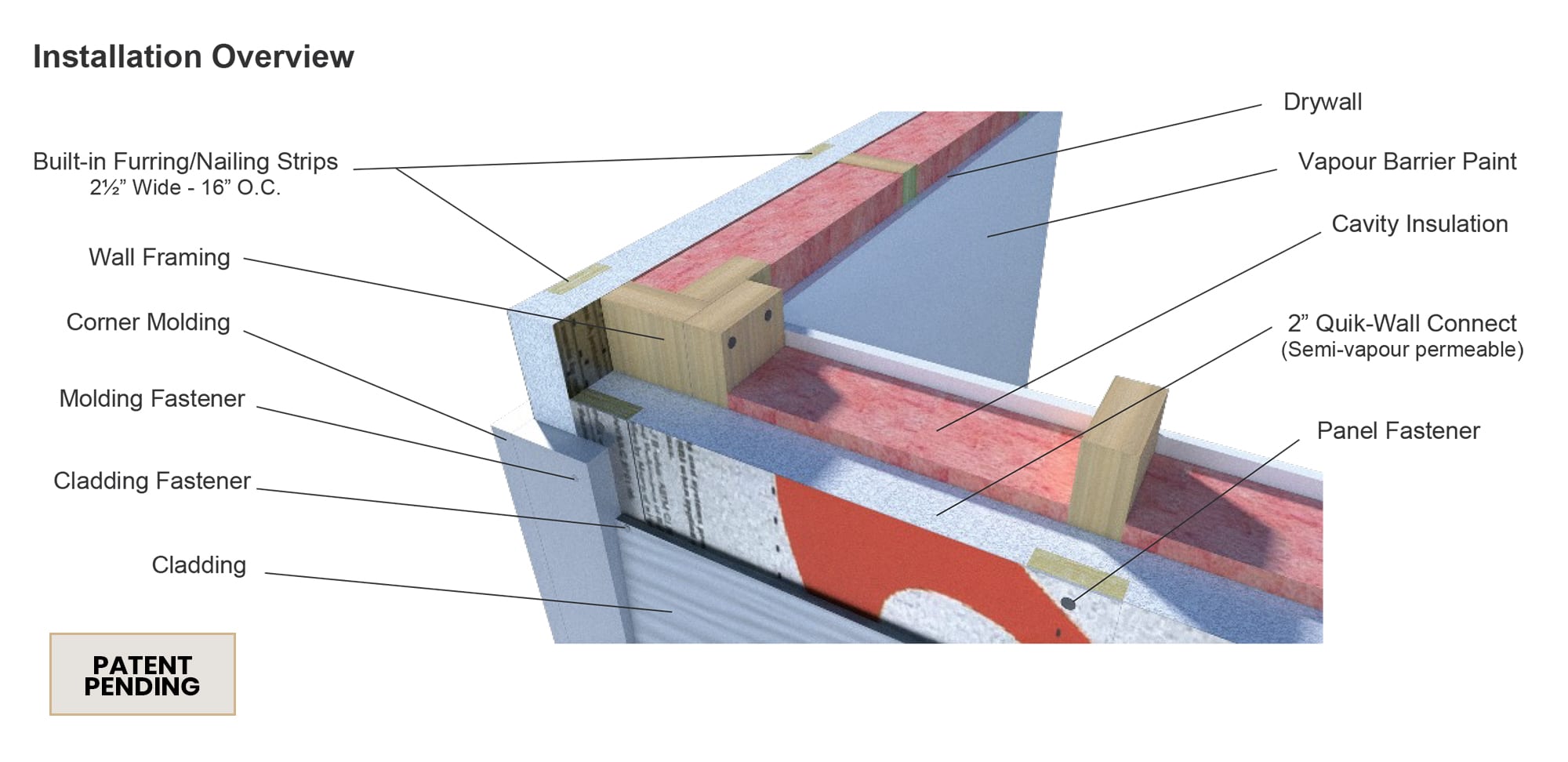

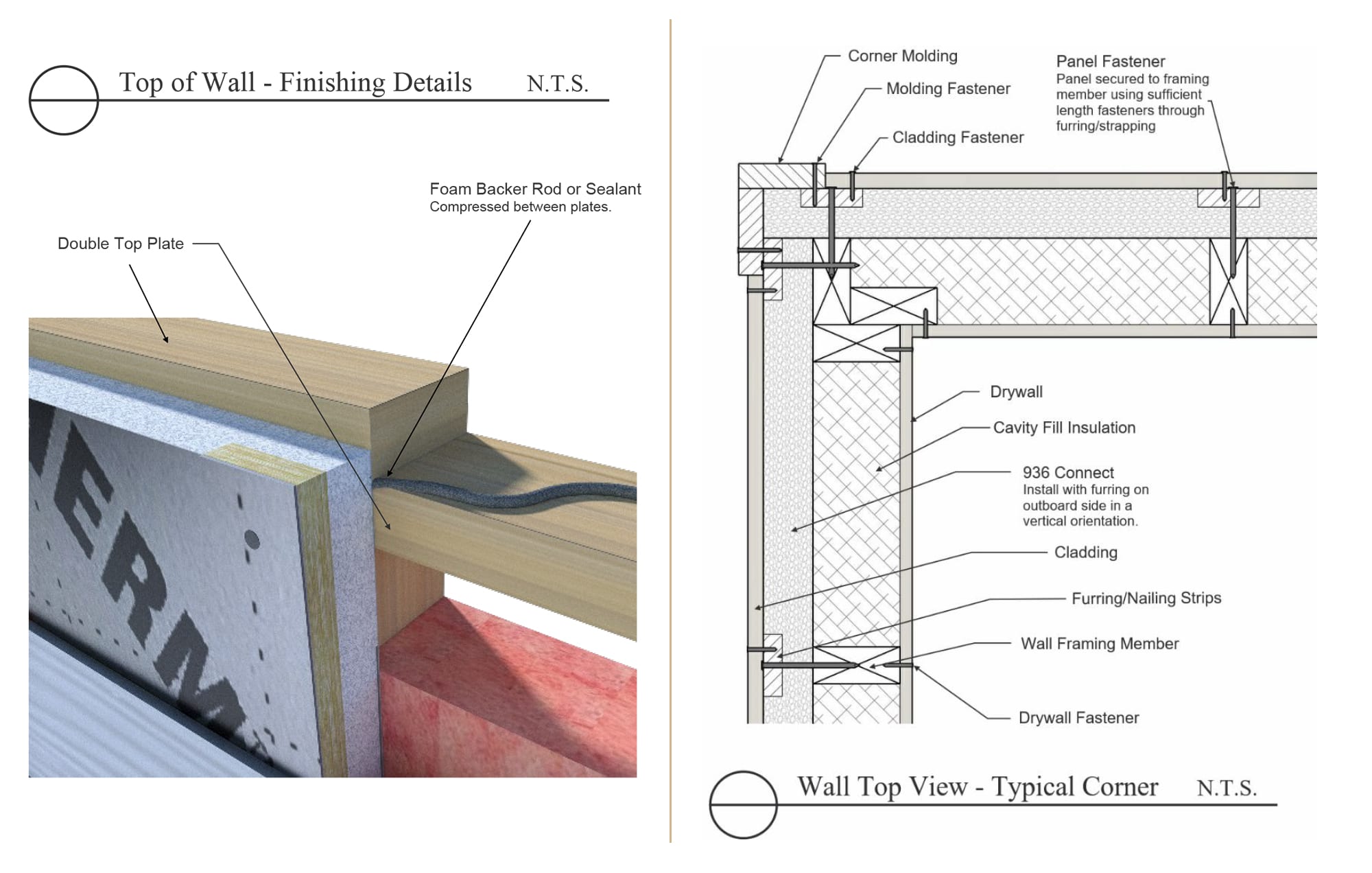

Moisture resistant, semi-vapour permeable continuous insulation system consisting of just three fundamental components. There is no requirement for exterior substrate sheathing (except seismic regions), house wrap or 6 mil poly. The pre-tension clamping design seals the all-encompassing air, vapour and thermal control layer to the wall framing system. The service stud bays contain 3.5” cavity batt insulation. Perforated polymer facers with 3/16” micro drainage channels allow the wall assembly to dry (diffuse) vapour both outward (winter) and inward (summer). There is no potential for a double vapour barrier. Vertical, micro, free air channels promote gravity induced drainage between 936 panels and exterior cladding. Tongue and Groove connections aide in panel alignment. Cladding materials are mechanically fastened to the inherent plywood furring/nailing strips.

Effective Thermal Resistance

In addition to nominal R-Value testing as per ASTM C518, QuikTherm Insulation Solutions Inc. has undertaken a program of fullscale thermal performance testing to ASTM C1363-05 “Standard Test Method for Thermal Performance of Building Materials and Envelope Assemblies by Means of a Hot Box Apparatus.”

- Type 2 Nominal R-Value Testing ASTM C-518 = R-4.18

- ASTM C1363 Effective R-Value Testing. Testing temperature range. +20C inside / -18C outside. Assembly configuration. ½” Drywall, 2×4 studs, R-13 batt, 7/16” OSB, 2” Connect, Cement Board = R-23.1

Wall Framing Requirements

936 Connect installs similar to exterior wall sheathing materials. However, there are a few framing requirements that must be considered to address structural integrity as well as moldings and trims. Please refer to Detail A for guidance and best practices.

National Building Code Canada

Canadian Provinces typically adopt the National Building Code of Canada (NBCC) as their provincial codes; however, some Provinces and Municipalities may add additional information reflecting modifications to meet local needs and concerns. Compliance with the code is achieved by complying with the acceptable solutions of Division B of the code. Division B, lays out the steps that must be followed, beginning with the geographic location where the build is taking place. The following are frequently asked questions regarding code compliance for the 936 Connect Wall Weatherization System.

1. Can a Part 9 building be constructed in Canada with rigid foam plastic insulation sheathing in lieu of plywood, OSB or

exterior gypsum?

Yes! Article 9.23.17.1. Required Sheathing Table 9.23.17.2.-A, Wall Sheathing and Thickness and Specifications lists permitted materials for use as sheathing in a Part 9 building. Polystyrene, expanded polystyrene (EPS) Types 1 and 2, meeting the CAN/ULC – S701.1 Material Standard are permitted in lieu of plywood, OSB and gypsum sheathing in a Part 9 building.

2. Does the NBCC require 2×6 studs when constructing a Part 9 building?

No! Article 9.23.10.1. Stud Size and Spacing Article 9.23.10.1. Stud size and Spacing in the NBCC, defines stud size and spacing allowed in Part 9 construction. Table 9.23.10.1. lists supported loads, minimum stud size, maximum stud spacing and the maximum unsupported height (of the stud), for use in interior and exterior walls. For exterior walls supporting a “Roof with or without attic storage plus one floor”, 2×4 studs, spaced 16” O.C., to a maximum unsupported height (length of the wall stud) of 3.0 meters, are permitted for use in a Part 9 building.

3. Is polyethylene required for use as a vapour barrier in Part 9 construction?

No! Article 9.25.4.2. Vapour Barrier Materials Thermally insulated, heated buildings must have a vapour control layer incorporated into the building envelope (exterior walls) of a building, to prevent water vapour diffusion from the interior of the building, entering into the wall spaces. Article 9.25.4.2. of the NBCC describes a vapour barrier as a material having a vapour permeance, not greater than 60 ng/(Pa.s.m2) and requires it to be installed on the interior (warm side) of insulated walls, floors and roof spaces. Sentence four [9.25.4.2.(4)] permits the use of coatings to the drywall, such as vapour barrier paints with a vapour permeance ranging from between 45-60 ng/(Pa.s.m2) to act as the vapour control layer of the building envelope, in lieu of six mill poly.

4. Is an Air Barrier required in Part 9 Construction?

Yes? Article 9.25.3.1. Required Barrier to Air Leakage and 5.4.1.2. Air Barrier System Properties. An air barrier is required in wall, ceiling, and floor assemblies separating a heated space from an unconditioned space. Air barrier systems must create an effective barrier to air infiltration and exfiltration when exposed to a differential air pressure, from, stack effect, mechanical system’s or wind. Materials used as an air barrier must have an air leakage of not greater than 0.02 L /(s.m2) measured at a pressure difference of 75 pascals (Pa), when tested in accordance to ASTM E 2178.

Note: Quik-Therm performed two ASTM 2178 air permeance tests – one with laminates not breached and the other with laminates breached. The results from both tests met the requirements of an air barrier, as outlined in Section 5.4.1.2. in Division B, of the NBCC.

Receive details and installation instructions by email.