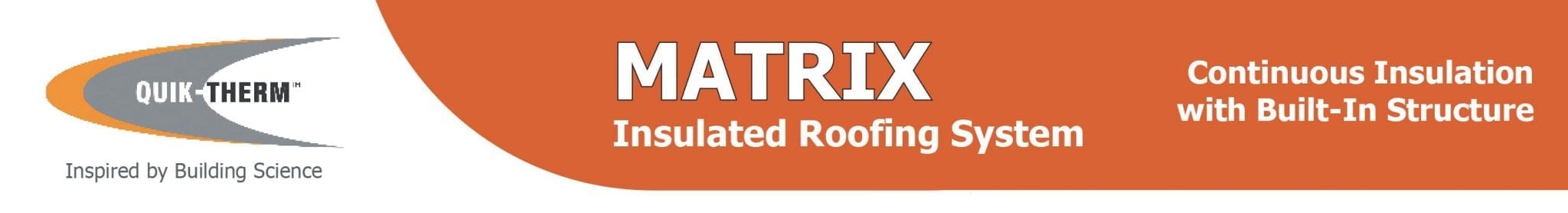

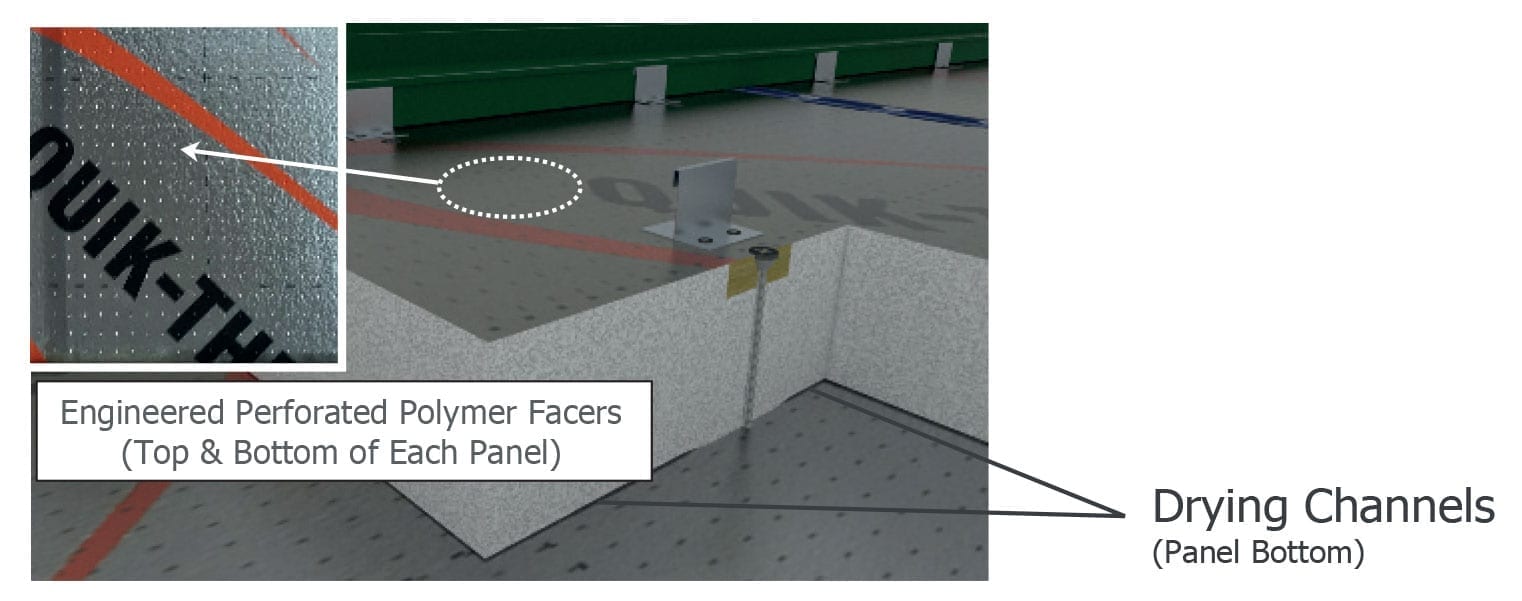

The Patent Pending Quik-Therm Matrix Insulated Roof System (Matrix) is a science based composite rigid foam roofing insulation technology. Matrix integrates simply, intuitively and quickly with metal standing seam and screw down roofs. Alternative cladding systems may require an exterior layer of wood sheathing and/or furring strips. Although developed for roofs, Matrix can be easily designed into thermal bridge free high performance wall systems. The Matrix system is vapour permeable, vented and perforated. Matrix consists of two or more layers of Quik-Therm Air Dry Connect running perpendicular to each other. Typically, the bottom layer runs peak to eave (high to low) and the top layer runs gable to gable (side to side). Spaced 16” OC., 3 precision 3/4” thick x 2.5” wide plywood battens (framing) are embedded into Type 2 EPS rigid foam panels. Perforated metalized polymer facers are laminated to both sides of the panels.

Virtually 100% Thermal Bridge Free

Robust, Lightweight & Stable.

Installs Intuitively, Fast and Easy

Building Science Validated.

Sustainable & Healthy.

The use of effective R-values when evaluating the thermal resistance of an assembly is preferable to using the nominal R-value of the insulation alone. The benefits of this approach have been demonstrated in results obtained through laboratory tests such as ASTM C1363 and by data published in ASHRAE 90.1. Quik-Therm Insulation Solutions Inc. has undertaken a program of full scale thermal performance testing to ASTM C1363-05 Standard Test Method for Thermal Performance of Building Materials and Envelope Assemblies. Temperature range: Outside -18C/Inside +21C with a 22 KPH wind/-31 wind chill.

-Mark Lawton – Senior Building Scientist, Morrison Hershfield

Thermal Performance – Matrix vs. Steel Framing

| Overall Insulation Thickness | Connect Panels (Two Layers) | Matrix Effective R-Value | Steel to Steel Girt Effective R-Value* |

|---|---|---|---|

| 6″ | 3” x 2 | R-28 | R-7 to R-10 |

| 7” | 3.5” x 2 | R-32 | R-8 to R-11 |

| 8″ | 4” x 2 | R-36 | R-9 to R-12 |

| 9″ | 4.5” x 2 | R-40 | R-10 to R-13 |

| 10″ | 5” x 2 | R-44 | R-11 to R-14 |

| 11″ | 5.5” x 2 | R-48 | R-12 to R-15 |

| 12″ | 6” x 2 | R-52 | R-13 to R-16 |

Nominal R-Value testing, ASTM C518 = R-4.18 per inch.

*RDH Building Science Inc. 2014. Thermal Bridging From Cladding Attachment Strategies Through Exterior Insulation

Environmentally Responsible

Quik-Therm’s expanded polystyrene (EPS) core comprises 98% air captured within a 2% cellular matrix. Food grade quality polymer facers are heat sealed to both sides of it’s core. Quik-Therm will not degrade over its service life and does not contain or use ozone depleting chemicals. Quik-Therm products may contain up to 15% pre or post consumer recycled EPS. EPS has received an A+ rating for most environmental matrices.

Typical Fastener Loads for Plywood and Metal

Ultimate/Nominal Pull-Out Resistance (lbf) S

Screw Diameter

| Column 1 | #8 | #10 | #12 | #14 |

|---|---|---|---|---|

| 20 Gauge Steel | 151.8 | 175.9 | 199.9 | 224.0 |

| 18 Gauge Steel | 197.8 | 229.2 | 260.5 | 291.9 |

| 16 Gauge Steel | 376.3 | 436.0 | 495.7 | 555.4 |

| 3/4” Plywood | 355.0 | 415.0 | 470.0 | 525.0 |

*Values for nominal steel stud withdrawal are based on calculations according to CSA S136 and could be considered ultimate level values. Ultimate pull-out values based on testing for specific fasteners may differ. *Values for plywood ultimate withdrawal are taken from APA Technical Note #E830E.

Don’t settle for uncertified or underrated knockoffs – Look for the seals of approval on your product.

For full specs & technical information please download this file.